Pressure die-casting are not always perfectly impermeable to gas and liquids. Microporosities,

created during the pressure die-casting process, are often invisible or

emerge during machining.

Vacuum impregnation, can solve once and for all most leaking problems.

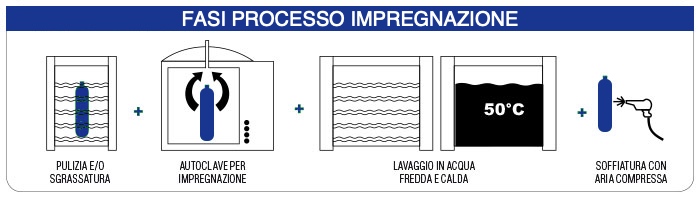

Impregnation is operated in autoclave and it consists of filling, with

special resins, all microcavities present on the surface or hiding deeper

in the pieces. A sequence of washings follows, to clean the pieces from

silicate residuals. In most cases, impregnation, is one of the stages

provided in the processing of pieces: such a stage, in Comer, can be

carried out without any further logistic handlings.

VACUUM IMPREGNATION

The impregnation plant is internal the firm site and allows Comer

to rapidly solve, without further logistic costs, any porosity problem.

Impregnation stage is complementary to the leaking tests one